Introduction

Almond extract, derived from almonds, is a popular flavoring agent widely used in the food and beverage industry, baking, cosmetics, and pharmaceuticals. Its distinct flavor and aroma make it a sought-after ingredient in various culinary applications. With the increasing demand for natural flavoring agents and the rising popularity of almond-based products, establishing an almond extract manufacturing plant presents a lucrative opportunity. This Almond Extract Manufacturing Plant Project Report outlines the essential aspects of setting up an almond extract manufacturing facility, including market analysis, production processes, equipment requirements, financial projections, and potential challenges.

Market Analysis

Global Demand

The global demand for almond extract has been steadily increasing due to several factors:

- Growing Health Consciousness: Consumers are increasingly leaning towards natural and organic flavoring agents, driving the demand for almond extract.

- Expanding Food and Beverage Industry: The rise in bakery products, beverages, and gourmet foods featuring almond flavors is propelling market growth.

- Cosmetic and Pharmaceutical Applications: Almond extract is also used in cosmetics and personal care products, further boosting its demand.

Regional Insights

- North America: The United States is a significant market for almond extract, with high consumption in the baking and confectionery sectors.

- Europe: Countries like Germany and France are major consumers, driven by the gourmet food trend and increasing interest in natural flavors.

- Asia-Pacific: Rapid urbanization and changing consumer preferences in countries like India and China present substantial growth opportunities for almond extract manufacturers.

Get a Free Sample Report with Table of Contents@

Competition

The almond extract market features a mix of established players and emerging companies. Key competitors include both large-scale manufacturers and small artisanal producers. Understanding the competitive landscape is crucial for new entrants looking to carve out their niche.

Project Description

Objectives

The primary objective of establishing an almond extract manufacturing plant is to produce high-quality almond extract that meets industry standards and caters to both domestic and international markets. The project aims to ensure regulatory compliance while achieving profitability.

Location

Choosing the right location for the manufacturing facility is critical. Key considerations include:

- Proximity to almond sources, ensuring a steady supply of raw materials.

- Accessibility to transportation networks for efficient distribution.

- Availability of skilled labor in the area.

- Compliance with local regulations and zoning requirements.

Production Process

The manufacturing process for almond extract generally involves several key steps:

- Raw Material Procurement: High-quality almonds are sourced, preferably organic, to ensure the best flavor and aroma.

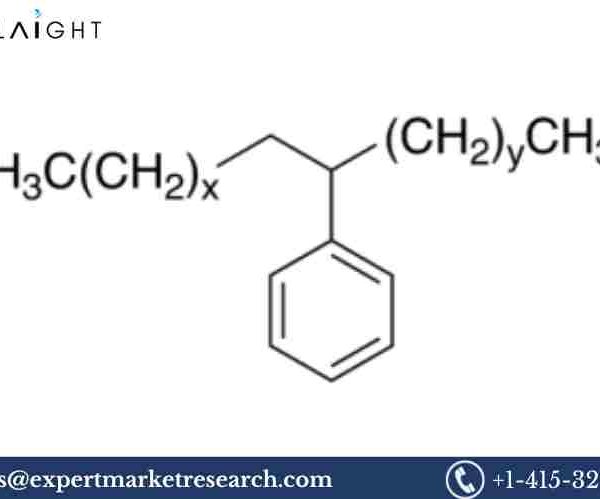

- Extraction: The extraction process typically uses alcohol (ethanol) as a solvent to extract flavor compounds from the almonds. The almonds are ground, and the alcohol is mixed with the ground almonds to extract the essential oils and flavors.

- Filtration: The mixture is then filtered to separate the solid almond residues from the liquid extract.

- Concentration: The extract may undergo concentration processes to enhance flavor intensity and shelf life.

- Packaging: The final almond extract is packaged in suitable containers, ensuring proper sealing to maintain freshness.

- Distribution: The packaged products are distributed to various sectors, including food manufacturers, bakeries, and cosmetic companies.

Equipment and Technology

Essential equipment for an almond extract manufacturing plant includes:

- Grinding Machines: For grinding almonds into a fine paste.

- Extraction Equipment: Including ethanol extraction units for efficient solvent extraction.

- Filtration Systems: To separate liquid extracts from solid residues.

- Concentration Units: For enhancing flavor concentration and extending shelf life.

- Packaging Machinery: For efficient packaging of the final product.

Financial Projections

Startup Costs

Startup costs for an almond extract manufacturing plant encompass several factors, including:

- Land Acquisition: The cost of purchasing land for the facility.

- Construction Costs: Expenses related to building the manufacturing plant and necessary facilities.

- Equipment Purchases: Investment in machinery and technology for production.

- Licensing and Permits: Costs associated with obtaining necessary regulatory approvals.

- Working Capital: Funds required for raw materials, labor, and operational expenses.

Revenue Projections

Revenue generation will depend on factors such as production capacity, market demand, and pricing strategies. A comprehensive market analysis is essential to accurately forecast potential sales volumes.

Profitability Analysis

The profitability of the plant will be influenced by several elements:

- Production Efficiency: Maximizing output while minimizing waste is crucial.

- Market Prices: Fluctuations in the price of raw materials and competition can impact profit margins.

- Operational Costs: Effective management of labor, energy, and material costs is essential for financial health.

Break-even Analysis

Conducting a break-even analysis is vital to determine when the plant will start generating profits. This analysis should consider fixed and variable costs alongside expected sales volumes.

Environmental Considerations

Establishing an almond extract manufacturing plant requires attention to environmental responsibilities. Key considerations include:

- Waste Management: Implementing strategies for effective disposal and recycling of almond residues.

- Compliance with Environmental Regulations: Adhering to local regulations regarding emissions and waste disposal.

- Sustainable Practices: Incorporating eco-friendly practices in the manufacturing process to minimize the ecological footprint.

Challenges and Risks

Market Fluctuations

The almond extract market can experience volatility, with changes in demand affecting profitability. Manufacturers must stay informed about market trends and adapt strategies accordingly.

Regulatory Compliance

Navigating the complex regulatory landscape can be challenging. Continuous monitoring and compliance efforts are essential to avoid penalties and ensure product safety.

Supply Chain Disruptions

Disruptions in the supply chain for raw materials can impact production schedules. Building strong relationships with suppliers and maintaining adequate inventory levels can help mitigate these risks.

FAQs

1. What is almond extract used for?

Almond extract is primarily used as a flavoring agent in baking, cooking, and confectionery, as well as in cosmetics and pharmaceuticals.

2. What are the main raw materials for producing almond extract?

The main raw material is high-quality almonds, preferably organic, to ensure optimal flavor and aroma.

3. What is the production process for almond extract?

The production process involves procuring almonds, extracting flavors using alcohol, filtering the mixture, concentrating the extract, and packaging the final product.

4. What are the key challenges in establishing an almond extract manufacturing plant?

Key challenges include market fluctuations, regulatory compliance, supply chain disruptions, and maintaining production efficiency.

5. How can I assess the profitability of an almond extract manufacturing plant?

Profitability can be assessed through detailed financial projections, including startup costs, revenue forecasts, operational costs, and break-even analysis.

6. What environmental considerations should be taken into account?

Manufacturers should focus on effective waste management, compliance with environmental regulations, and implementing sustainable practices to minimize their ecological impact.

Related Reports

https://www.expertmarketresearch.com/articles/top-5-companies-in-the-global-organic-pet-food-market

https://www.expertmarketresearch.com/reports/earphones-and-headphones-market-report

https://www.expertmarketresearch.com/reports/smart-speaker-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au