Dubai, a global hub of innovation and technology, has rapidly embraced 3D printing technology across various industries.

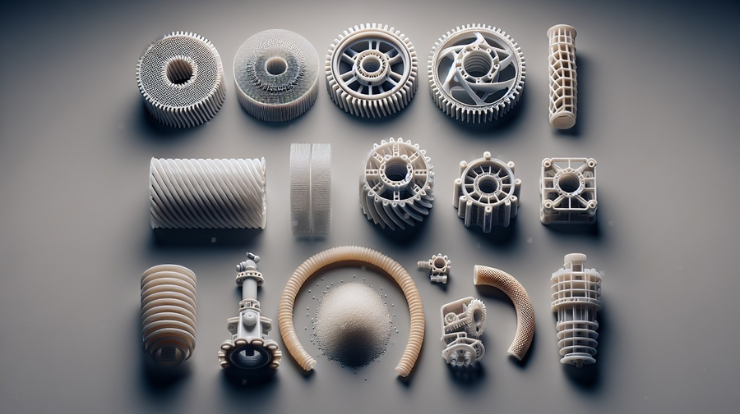

The adoption of 3D printed spare parts is transforming traditional manufacturing and supply chain processes, offering significant benefits in terms of cost, efficiency, and customization. Here are the industries in Dubai that benefit the most from 3D printed spare parts.

Aerospace and Aviation

Enhanced Efficiency and Cost Reduction

The aerospace and aviation industry in Dubai has seen substantial benefits from the adoption of 3D printed spare parts. The ability to produce lightweight and complex components quickly reduces manufacturing costs and lead times. Additionally, 3D printing allows for the creation of parts with intricate geometries that are difficult or impossible to achieve with traditional manufacturing methods.

Customization and Rapid Prototyping

With 3D printing Dubai, aerospace companies can produce customized parts tailored to specific aircraft models and requirements. Rapid prototyping capabilities enable faster design iterations, helping engineers to quickly test and refine parts before final production.

Automotive Industry

Lightweight Components for Fuel Efficiency

In the automotive industry, reducing the weight of vehicles is crucial for improving fuel efficiency. 3D printed spare parts allow manufacturers to create lightweight components without compromising strength and durability. This technology enables the production of complex geometries that enhance the performance and efficiency of automotive parts.

On-Demand Manufacturing

3D printing offers on-demand manufacturing capabilities, which means that spare parts can be produced as needed. This reduces the need for large inventories and minimizes storage costs. Automotive companies in Dubai can quickly produce replacement parts, reducing vehicle downtime and improving customer satisfaction.

Healthcare and Medical Devices

Customized Implants and Prosthetics

The healthcare industry in Dubai is leveraging 3D printing to produce customized medical implants and prosthetics. This technology allows for the creation of patient-specific parts that fit perfectly, enhancing the comfort and effectiveness of medical devices. Surgeons can also use 3D printed models for pre-surgical planning, improving the accuracy of complex procedures.

Rapid Production of Medical Equipment

During emergencies or medical crises, the ability to rapidly produce essential medical equipment is crucial. 3D printing enables the quick fabrication of critical components, such as ventilator parts and protective gear, ensuring that healthcare providers have the necessary tools to treat patients effectively.

Construction and Architecture

Innovative Building Components

Dubai’s construction and architecture industry is known for its ambitious and innovative projects. 3D printing technology allows for the creation of unique and complex building components that enhance the aesthetics and functionality of structures. Architects can experiment with new designs and materials, pushing the boundaries of traditional construction methods.

Sustainable Building Practices

3D printed spare parts contribute to sustainable building practices by reducing material waste and energy consumption. The ability to produce components on-site also minimizes transportation costs and environmental impact. This aligns with Dubai’s commitment to sustainable development and green building initiatives.

Maritime and Offshore Industry

Durable and Corrosion-Resistant Parts

The maritime and offshore industry in Dubai benefits from 3D printed spare parts that are durable and resistant to harsh marine environments. This technology allows for the production of components with enhanced mechanical properties and corrosion resistance, extending the lifespan of maritime equipment.

Reduced Downtime for Repairs

With 3D printing, maritime companies can produce spare parts quickly, reducing downtime for repairs and maintenance. This is particularly important for offshore platforms and vessels that operate in remote locations where access to replacement parts can be challenging.

Energy and Utilities

Improved Efficiency of Power Plants

The energy and utilities sector in Dubai is utilizing 3D printing to improve the efficiency and performance of power plants. 3D printed spare parts can be customized to optimize the flow and combustion processes within turbines and other equipment. This leads to increased energy efficiency and reduced operational costs.

Maintenance and Repair Solutions

3D printing offers flexible maintenance and repair solutions for the energy sector. Companies can produce spare parts on-site, minimizing downtime and ensuring the continuous operation of critical infrastructure. This technology also enables the refurbishment of worn or damaged parts, extending their useful life.

Consumer Goods and Electronics

Customization and Personalization

In the consumer goods and electronics industry, 3D printing allows for the customization and personalization of products. Companies in Dubai can produce spare parts tailored to individual customer preferences, enhancing the user experience and adding value to their offerings.

Rapid Product Development

3D printing accelerates the product development cycle by enabling rapid prototyping and testing. Manufacturers can quickly iterate on designs, bringing new products to market faster. This agility is crucial in the competitive consumer goods and electronics sector.

Education and Research

Hands-On Learning and Innovation

Educational institutions in Dubai are incorporating 3D printing into their curricula to provide hands-on learning experiences. Students can design and create spare parts, fostering innovation and practical skills. Research facilities also benefit from 3D printing by producing specialized components for experiments and studies.

Collaboration with Industry

By collaborating with industry partners, educational institutions can develop cutting-edge 3D printing applications. This synergy between academia and industry drives technological advancements and prepares students for careers in emerging fields.

Conclusion

The adoption of 3D printed spare parts is revolutionizing various industries in Dubai, from aerospace and automotive to healthcare and construction. This technology offers numerous benefits, including cost reduction, improved efficiency, customization, and sustainability.

As Dubai continues to embrace 3D printing, its industries will undoubtedly experience further innovation and growth, solidifying the city’s position as a global leader in technology and manufacturing.