Duct fittings are essential components of HVAC (Heating, Ventilation, and Air Conditioning) systems, as they connect different sections of ductwork and allow for changes in direction, size, or shape of the ducts. The proper selection and installation of duct fittings are crucial for maintaining efficient airflow, minimizing pressure loss, and ensuring the overall performance of the HVAC system. Below, we explore the various types of duct fittings, their functions, and their impact on system performance.

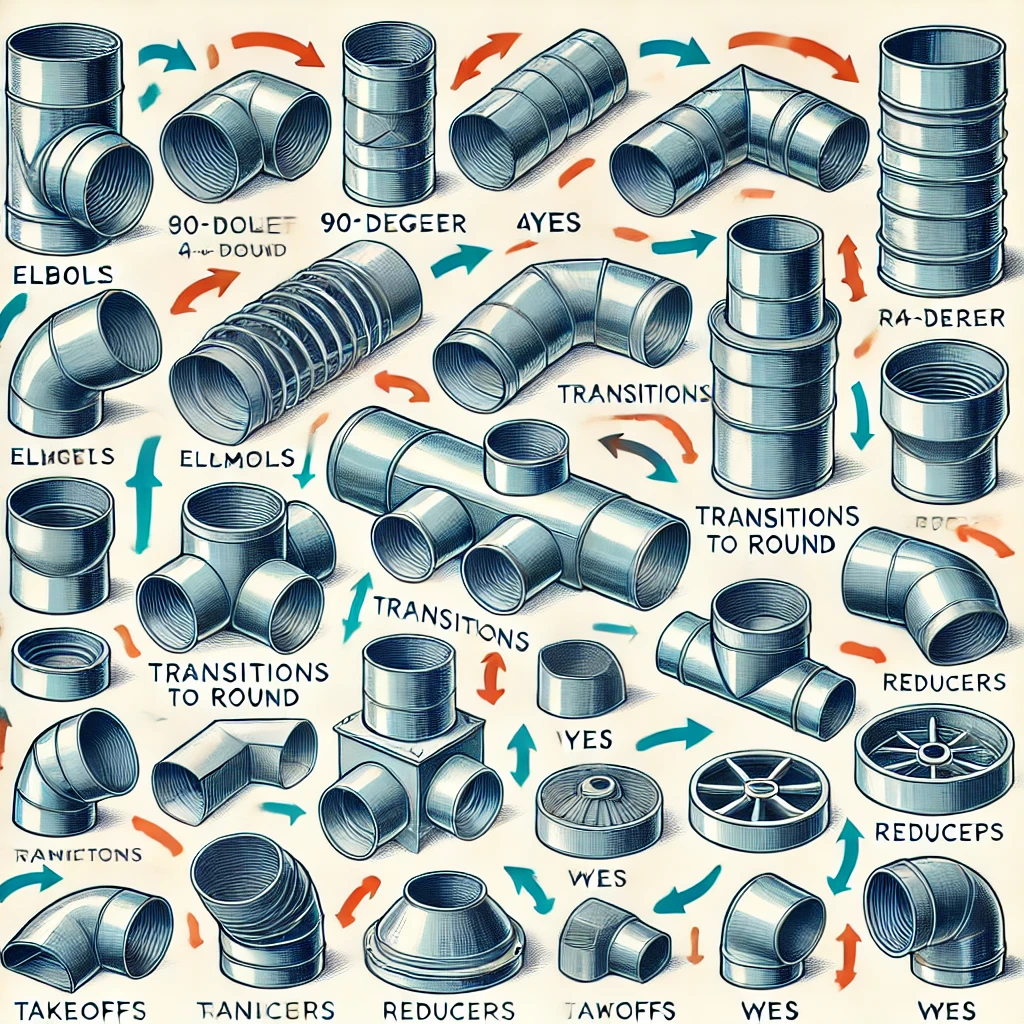

1. Elbows:

Function: Elbows are used to change the direction of airflow in a duct system, typically by 90 degrees or 45 degrees. They are available in various angles and configurations, including short-radius and long-radius elbows.

Impact on Airflow: Elbows introduce resistance to airflow, especially short-radius elbows, which can create more turbulence and pressure drop compared to long-radius elbows. This can reduce the efficiency of the system, leading to higher energy consumption. Long-radius elbows are preferred in situations where smooth airflow and minimal pressure loss are critical.

2. Transitions:

Function: Transitions are fittings that connect ducts of different sizes or shapes. They are used to move from a larger duct to a smaller one or from a rectangular duct to a round duct (or vice versa).

Impact on Airflow: Transitions can significantly impact airflow if not designed correctly. A sudden change in duct size or shape can create turbulence, leading to a drop in pressure and reduced airflow efficiency. Smooth, gradual transitions are preferred as they help maintain laminar flow and minimize pressure loss.

3. Tees and Wyes:

Function: Tees and wyes are fittings used to split or merge airflow in the duct system. A tee fitting typically splits the airflow into two perpendicular directions, while a wye fitting splits the airflow into two directions at an angle, usually 45 degrees.

Impact on Airflow: The design of tees and wyes affects how evenly the airflow is distributed across the branches. Wyes are generally more efficient than tees because they introduce less turbulence and pressure loss. Tees can cause significant resistance and uneven airflow if not carefully sized and installed.

4. Dampers:

Function: Dampers are adjustable fittings that control the volume of airflow in a duct system. They can be installed within the duct or at the air outlet to regulate airflow to specific zones or rooms.

Impact on Airflow: Dampers are crucial for balancing airflow in different parts of the HVAC system. By adjusting the damper, you can increase or decrease airflow to specific areas, ensuring comfort and efficiency. However, improperly adjusted dampers can restrict airflow too much, leading to increased pressure and energy consumption.

5. Takeoffs:

Function: Takeoffs are used to create a branch from a main duct, allowing air to be distributed to multiple locations. They can be simple, straight connections or include dampers for better airflow control.

Impact on Airflow: The design of takeoffs affects how air is diverted from the main duct. Improperly designed or installed takeoffs can cause significant turbulence and pressure loss, leading to reduced airflow to the branches. Including a damper in the takeoff can help control and balance the airflow.

6. Reducers:

Function: Reducers are fittings that gradually decrease the size of the duct, transitioning from a larger diameter to a smaller one. They are used when the airflow needs to be concentrated into a smaller area.

Impact on Airflow: Reducers, when properly designed, can minimize turbulence and maintain smooth airflow. However, abrupt or poorly installed reducers can cause significant pressure loss, reducing the overall efficiency of the system.

7. End Caps and Plenums:

Function: End caps are used to close off the end of a duct, while plenums are large, box-like fittings that serve as central distribution points for air, connecting multiple ducts together.

Impact on Airflow: End caps must be securely installed to prevent air leakage, which can compromise system efficiency. Plenums should be designed to distribute air evenly to connected ducts, minimizing turbulence and ensuring balanced airflow.

Conclusion:

Duct fittings play a crucial role in the design and performance of an HVAC system. Each fitting type serves a specific purpose, whether it’s changing the direction of airflow, connecting different duct sizes, or controlling the volume of air delivered to various areas. The impact of these fittings on airflow and system efficiency cannot be understated. Poorly designed or installed fittings can lead to significant pressure loss, increased energy consumption, and uneven air distribution, all of which negatively affect the overall performance of the HVAC system.

Place your online orders: https://www.ductingsuppliesuk.com/shop-online

To ensure optimal system performance, careful consideration must be given to the selection, sizing, and installation of duct fittings. This includes using long-radius elbows, smooth transitions, and properly adjusted dampers to maintain efficient airflow and minimize pressure losses. By doing so, HVAC systems can operate more efficiently, providing consistent comfort and reducing operational costs.